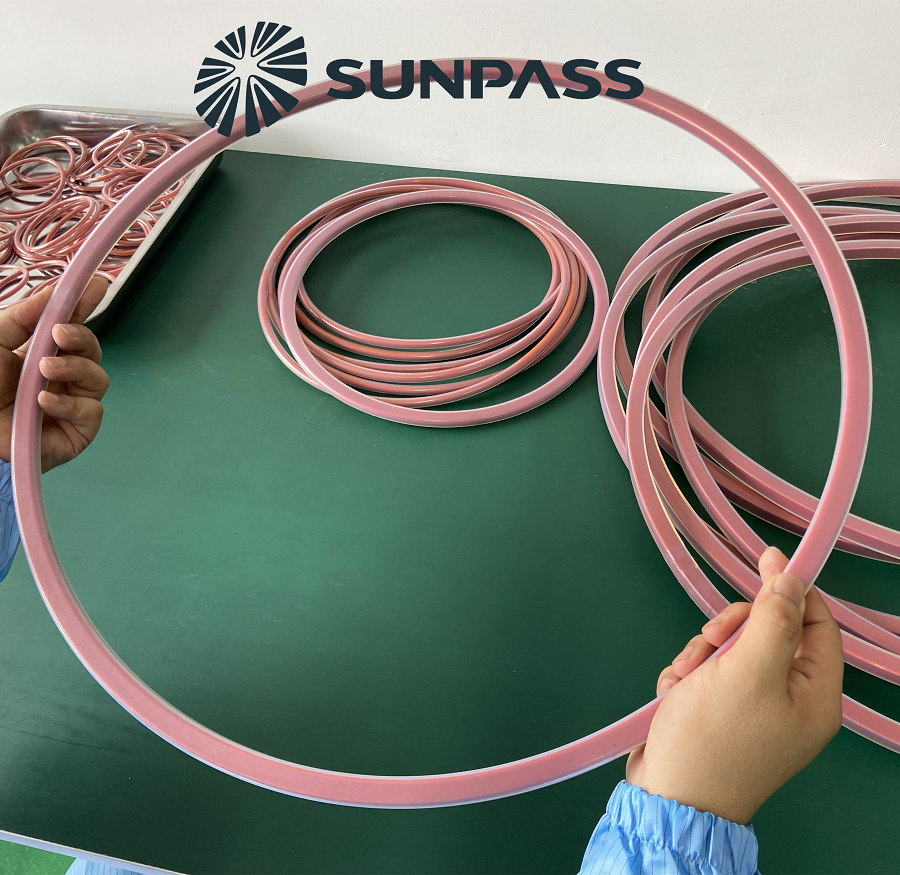

Reducing costs and increasing efficiency has always been our company's development strategy. We have been working hard to improve the quality of O-ring products, reduce costs, and bring cost-effective products to customers. We do:

First, try to reduce the probability of impurities inside the O-ring.

The workshop is built in accordance with dust-free standards, and the floor is made of epoxy flooring. Front-line employees put on professional dust caps, anti-static clothing, and anti-static shoes before entering the workshop. Each workshop is equipped with a dust removal device.

Second, strictly control raw materials to ensure product performance.

We focus on the physical properties such as rebound rate, hardness, tensile strength, and hardness of our products. High-quality raw material suppliers at home and abroad are selected. Each batch of raw materials requires the manufacturer to provide a factory inspection report. Before each production, it is inspected on the machine and sent to a third-party testing agency for inspection from time to time. There is a test report from SGS, and every indicator complies with industry standards. We have also standardized the entry and exit of materials into and out of the warehouse. Every entry and exit is recorded, and every order can be traced back to the batch of raw materials, operators and equipment stations.

Third, improve the interface processing process, independently develop and upgrade equipment, and strengthen pre-job and on-the-job training for employees.

The handling of the interface is definitely the first factor in testing the quality of O-rings. The O-ring workshop is equipped with 2 technicians with more than 8 years of experience, and more than 80% of the employees have more than 3 years of experience. One-week off-the-job pre-job training, and on-the-job training implement the old-to-new system. Make sure the interface transition is natural and the connection is firm.

Fourth, strict quality inspection.

We will conduct 5-6 inspections for each O-ring, including initial inspection of incoming materials, machine inspection of raw materials, initial size inspection, semi-finished product inspection, full finished product inspection, and factory sampling inspection. Ensure that unqualified finished products do not flow into the next production link and that unqualified products do not leave the factory.

SUNPASS,SINCE 2000, leading manufactory, developer, and supplier of quality ISO tank container spare parts and valve accessories, including manlid PTFE Braided seal, super tank seal, manlid clamp, PTFE flange gasket, CNAF/PTFE gaskets, O ring, dust cap, flange, flame gauze, one way ball, thermometer, pressure gauges, documents holder, data plate, walk way, valve and so on. Supplier of CIMC, Singamas. ITCO member. Isotank Cleaning,Isotank Depot, Isotank Repair, Maintain, Isotank service,Isotank terminal,isotank manlid

Manufacturer,Container & Fittings.

For more details, please visit www.sealings.cn

Welcome to mail: [email protected] or call at +86-574-62837603