PTFE packing is one of the most commonly used packing materials in the industry. It is a versatile material that can be used in a wide range of applications. It is extremely resistant to a variety of chemicals and is very durable. It has a very low coefficient of friction and is used in a number of pump and valve applications. It is also very resistant to heat and is not easily oxidized by strong chemicals. PTFE can also be used in applications that would not normally be compatible with elastomers. It is especially useful in high speed and clean applications.

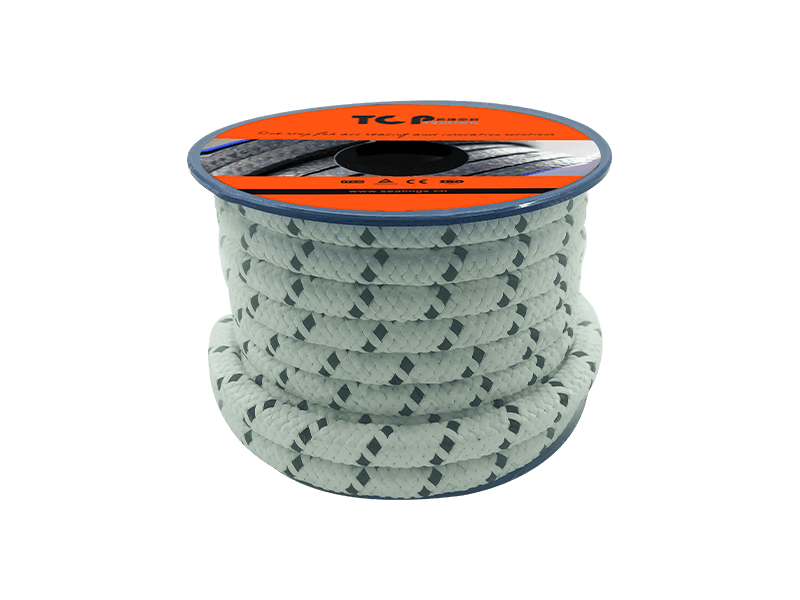

The materials used to manufacture PTFE packing are carbon and graphite fiber braids that are impregnated with a PTFE coating. These materials are among the most versatile, with their excellent chemical resistance and resilience. These braids are very abrasion resistant, have no tendency to soften at high temperatures, and are also very durable. They can be used in a wide range of industrial applications, and are particularly helpful in preventing fluid leaks in high pressure environments.

PTFE braided packing is an excellent material for valve applications. The material is very resilient, and its lubrication provides low friction during operation. It is ideal for a variety of valves, including pumps, and is especially effective in preventing fluid leaks. This type of valve packing is often used in the chemical and food industries, and is especially useful for sealing shafts in chemical processes. It is also useful for valves in a wide range of manufacturing processes. The material is able to withstand high linear speeds, and its self-lubricating properties ensure a reliable seal.

PTFE packings can also be reinforced with lubricant, which helps to reduce wear and friction. They are a great choice for pump and valve applications, and can be found in a number of different types. They are particularly useful in preventing damage due to aggressive chemicals, and are especially suitable for high speed and clean applications. They can also be reinforced with waterproofing to prevent corrosion. They are a good choice for pumps, valves, and even metal flanges. They are also resistant to corrosive chemicals, and have a wide range of chemical resistance.

PTFE can be combined with a variety of other materials, including glass fiber and carbon fiber. This allows for a variety of different packing configurations that are very useful. The PTFE material is very resistant to a variety of chemicals, and is especially durable for high-speed applications. It is also very resistant to fire and corrosion, and it has a high coefficient of thermal expansion. It is especially resistant to a number of corrosive fluids, and it has a temperature range of -400 degF to 850 degF.