Have you also encountered a situation where the oil leakage from the packing causes oil to accumulate on the wall of the tank? This issue not only greatly increases labor costs, but also affects container handling speed and even reputation.

So, why did this phenomenon occur? Let's take a look at the difference between these two Manlid Seals.

|

|

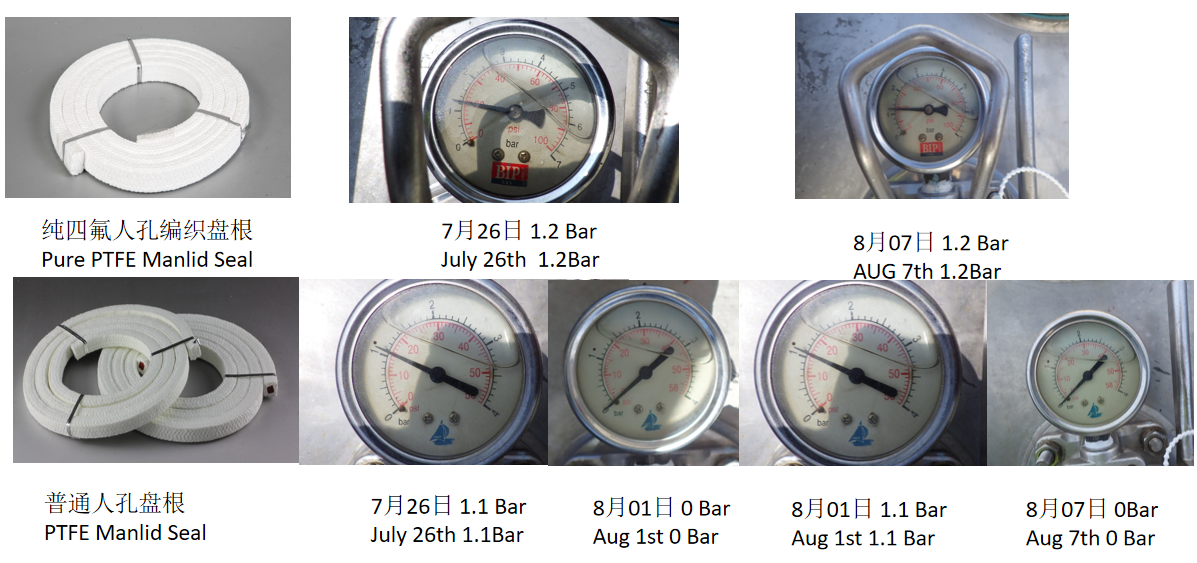

Pure PTFE Manlid Seal |

PTFE Manlid Seal |

|

Ingredients |

PTFE yarn |

PAN fiber impregnated PTFE lotion |

|

Oil Phenomenon |

None |

Occasionally |

|

Chemical Resistance |

Extremely Excellent |

Average |

|

Temperature Resistance |

-200℃ ~ +260℃ (It can reach 280 ℃ in a short time) |

-40℃ ~ +120℃ (It can reach 150 ℃ in a short time, but it will harden) |

|

Sealing Performance |

Excellent |

Good |

|

Cleanliness |

Clean and pollution-free, meeting food grade standards |

Non food grade |

|

Cost |

Relatively high |

Cost-effective |

|

Disadvantages |

Low thermal conductivity, prone to cold flow |

PTFE lotion is easy to be washed |

Reason

Based on the above, we can see that different chemical compositions fundamentally determine whether the phenomenon of “oil” will occur.

The PTFE Manlid Seal for tanks does not contain any oil in production, but ordinary fibers are easy to absorbing water. It is easy to absorb water in rainstorm, humid weather and extreme high low temperature difference weather. When the water is mixed with the impregnated PTFE lotion and under the high temperature and high pressure, the emulsifier will be diluted. This emulsifier is what we usually refer to as “ oil”.

Suggestion

So in areas with heavy rainfall and large temperature differences, we recommend using pure PTFE manhole packing to fundamentally solve this problem.

More advantages

Using pure PTFE manlid seals instead of ordinary ones can not only reduce after-sales and losses, but also increase the timeliness of sealing. The following is a pressure holding test experiment conducted by a Korean customer at the depot, which shows that the pressure holding time of pure PTFE manhole packing exceeds one week. And the pressure holding capacity of ordinary manlid seeal is less than one week.

What are the advantages of the pure PTFE manhole packing produced by SunPass?

Raw materials: Made from high-quality PTFE from Top 3 manufacturers such as Dongyue and Chengguang→better chemical resistance and compression resistance, and meeting food grade requirements

Equipment: Using German Style braiding machines → Weaving is tighter and has better sealing performance

Quality Management: Dual support of ISO9001 quality system and 6S on-site management → Stable quality