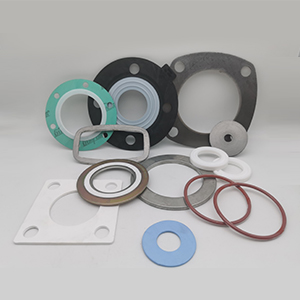

Gasket

TOP SEALING manufacturers and supplys many difference sealing gasket and sheet, e.g. PTFE gasket and sheet, PTFE joint sealant, PTFE envelop gasket, metal jacked graphite sheet, non asbestos sheet, graphite gasket and sheet, rubber sheet.

- Types of Gaskets and Sheets Gaskets and sheets come in various types, each designed for specific purposes and conditions. Some of the most common types include: 1.Soft gaskets: Soft gaskets are made of compressible materials, such as rubber, cork, or non-asbestos, and are used in low-pressure, low-temperature, or non-corrosive applications. They are easy to install, conform to irregular surfaces, and provide a low-cost sealing solution. 2.Metal gaskets: Metal gaskets are made of thin layers of metal, such as stainless steel, copper, or aluminum, and are used in high-pressure, high-temperature, or corrosive applications. They provide a reliable and durable sealing solution, but require precise machining and installation. 3.Compressed sheets: Compressed sheets are made of fiber materials, such as graphite, aramid, or PTFE, compressed with a resin binder to create a dense and homogeneous material. They are used in various industries, from chemical and petrochemical to power and marine, and are suitable for high-temperature, high-pressure, or corrosive environments.

- Applications of Gaskets and Sheets Gaskets and sheets have a wide range of applications in different industries, including: 1.Pipelines: Gaskets and sheets are commonly used in pipelines, where they help prevent leakage from flanges or joints and maintain a stable flow rate. They are used in various types of pipelines, such as oil and gas, water treatment, or food processing, and are suitable for different pressure and temperature conditions. 2.Engines: Gaskets and sheets are also used in engines, where they help prevent leakage from the cylinder head or exhaust system and ensure proper combustion and emission control. They are used in various types of engines, such as automotive, marine, or industrial, and are suitable for different fuels and lubricants. 3.Electrical equipment: Gaskets and sheets are used in various types of electrical equipment, such as transformers, switchgear, or generators, where they help prevent moisture, dust, or vibration ingress and ensure proper insulation and performance. They are suitable for different voltage and frequency conditions.

- Benefits of Gaskets and Sheets Gaskets and sheets offer various benefits, including: 1.Leakage control: Gaskets and sheets help prevent leakage from various types of equipment and systems, reducing the risk of contamination, environmental damage, and safety hazards. 2.Versatility: Gaskets and sheets are suitable for a wide range of applications, materials, and environments, providing a flexible and cost-effective sealing solution. 3.Customization: Sheets can be cut or stamped into various shapes and sizes to create custom gaskets or seals, providing a precise and efficient sealing solution.

English

English русский

русский Español

Español