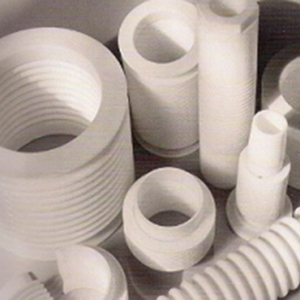

TOP SEALING manufactures a complete range of PTFE SHEET, ptfe sheet,expanded ptfe sheet.PTFE has a wide range of practicable temperature from -180°C - +260°C and a wax-like surface to which anything hardly plastics. PTFE has the lowest coefficient of friction of all known solid materials. It has the best electrical properties of all plastics.PTFE Sheet has excellent chemical resistance, low friction, high temperature resistance, electrical insulation and non-stick properties, used in transformers, cables, pumps, valves, pipes, bearings and hydraulic systems, widely used in chemical, machinery, military, food processing and packaging industries.

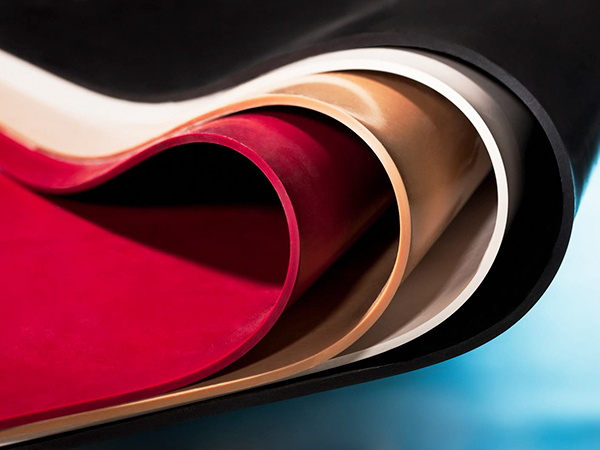

TOP SEALING manufactures rubber sheet, including natural rubber sheet, neoprene rubber sheet, EPDM rubber sheet, silicone rubber sheet. The oil-resisting, acid and alkali-resisting, cold and heat-resisting, insulation, etc. Rubber sheets have elasticity, durability, chemical resistance, and water resistance. Used as sealing rubber rings, rubber pads, door and window seals and laying workbenches and floors, widely used in military, aviation, industry and construction industries.

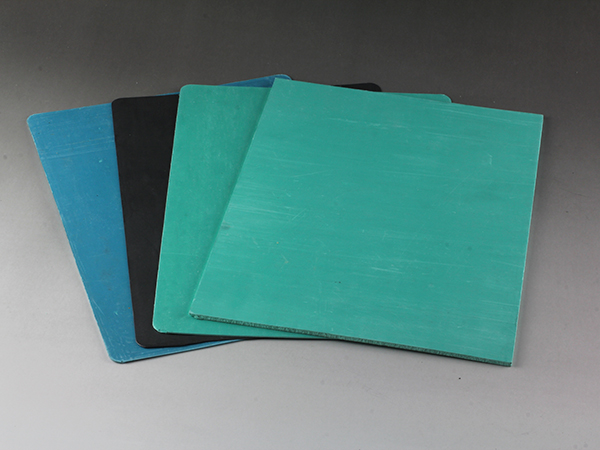

TOP SEALING manufactures non-asbestos rubber sheet,non asbestos beater sheet.It was utilised so widely in high temperature applications.Non-Asbestos Sheet has the performance of safety, chemical resistance, temperature resistance and versatility, used in valves, piping systems, automotive engines and chemical processing equipment, widely used in petroleum, chemical, pharmaceutical, marine, automotive, food and pharmaceutical industries.

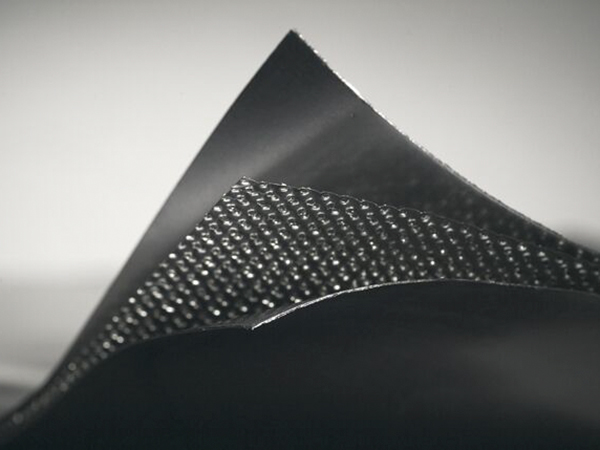

TOP SEALING manufactures graphite sheet, Flexible Graphite Paper,Flexible Graphite Sheet,Flexible Graphite Composite Sheet.Only natural graphite is used as a raw material, which yields highly flexible carbon with excellent heat resistance and chemical resistance. Rubber sheet has high thermal conductivity, chemical resistance, low friction, high compressibility properties, used in solar cells, heat exchangers, high temperature crucibles, automobile engines, compressors, widely used in metallurgy, chemical industry, electrochemical and other industries.

TOP SEALING manufactures mica sheet.Depending on your application, the correct mica sheet for an application depends on the material: Muscovite, or Phlogopite. Depending on the level of heat resistance needed, the thickness of mica sheet will also vary. Mica sheets are not uniform, and they can be ordered in various sizes and different degrees of smoothness based on the needs of the customer.Mica sheet has high temperature resistance, electrical insulation, chemical resistance, low thermal conductivity. Mica sheets are commonly used in generators, transformers, furnace liners, kilns, ovens, capacitors, transistors, automotive exhaust systems, widely used in metallurgy, chemical industry, household appliances and other industries.

TOP SEALING manufactures wool felt.It has high vibration absorption and abrasion resistance, flame retardancy. It has excellent wicking properties, is solvent resistant and has high stability in oil. Wool felt is used in the production of clothing, handicrafts, musical instruments, computer equipment, car engines, widely used in construction industry, home appliance industry, automobile manufacturing, aerospace industry and clothing industry.

TOP SEALING is famous China Sheet Manufacturers and Sheet factory. It is managed in strict accordance with the ISO9001:2008 standard and provides customers with high quality products and services. The products are exported to more than 200 countries and regions, and enjoys good reputation at home and abroad. We have passed ISO9001:2008, CE, TÜV. We custom OEM and ODM Sheet.