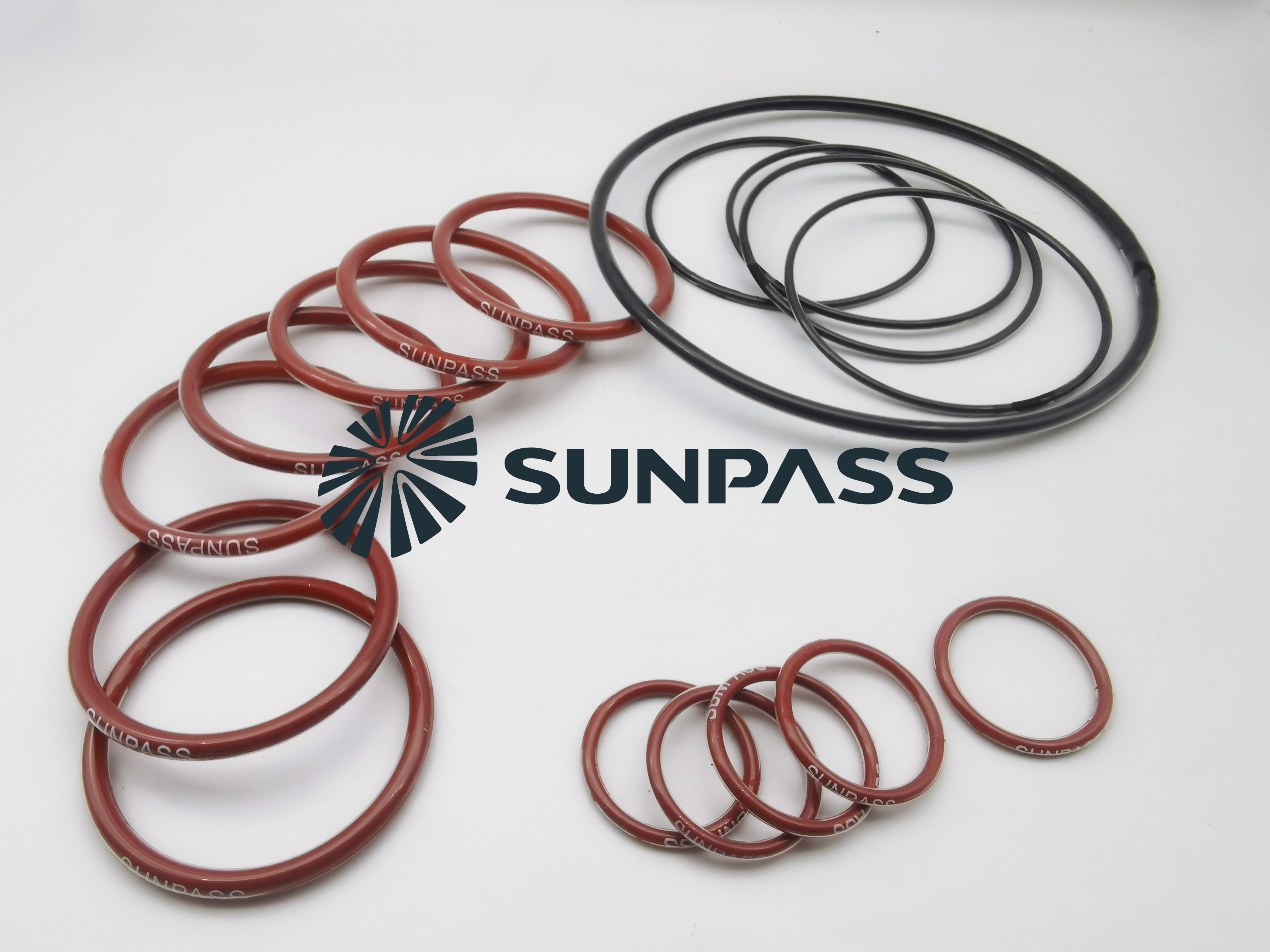

The FEP/PFAencapsulatedO-ring is a commonly used sealing element, valued for its simplicity, reliability, and cost-effectiveness, and is widely applied in various mechanical equipment and products. Here are the basic steps for correctly using encapsulated O-rings:

Before use, understand the working environment that the encapsulated O-ring will face, including temperature, medium (such as oil, water, gas, etc.), pressure, and speed of movement.

Choose the appropriate material, size, and hardness of the encapsulated O-ring based on the specific requirements of the application.

Before installation, check the encapsulated O-ring for any damage, cuts, deformation, or foreign matter embedded.

Ensure that the groove where the encapsulated O-ring will be installed is clean and free of burrs to avoid damaging the encapsulated O-ring.

If the encapsulated O-ring is coated (such as with a sealant or dust coating), make sure not to damage this protective layer during installation.

Use appropriate tools, such as special fixtures or lubricants (such as silicone oil or glycerin), to avoid damaging the encapsulated O-ring during installation.

Avoid overstretching the encapsulated O-ring, which could cause permanent deformation.

Ensure that the encapsulated O-ring is correctly installed in the groove without any twisting or flipping.

Slowly assemble the component containing the encapsulated O-ring into place to avoid impact from rapid assembly, which could damage the encapsulated O-ring.

After assembly, perform an initial leak test to ensure the encapsulated O-ring is functioning properly.

Maintenance and Replacement:

Regularly inspect the condition of the encapsulated O-ring and replace it in a timely manner based on usage.

Additional Considerations for FEP/PFA encapsulated:

Protective Layer:

FEP/PFA encapsulated usually have a protective layer for dust proof, anti-corrosion, or to enhance sealing performance. Handle with care during installation to avoid damaging this layer.

Compatibility:

Ensure that the material of the coating is compatible with the working medium and does not react chemically.